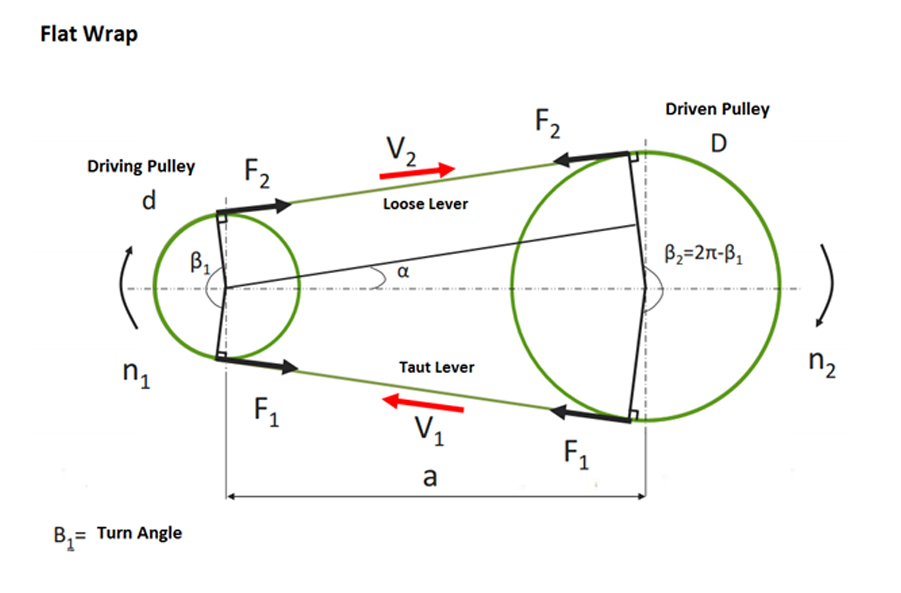

Effective friction coefficient μ μsinβ2- Ratio of belt forces T 1 T 2 expμα- Belt tension load T 1 T 1-T 21-T 2 T 1 N. Belt tension load T 2 T 1 T 2 T 1.

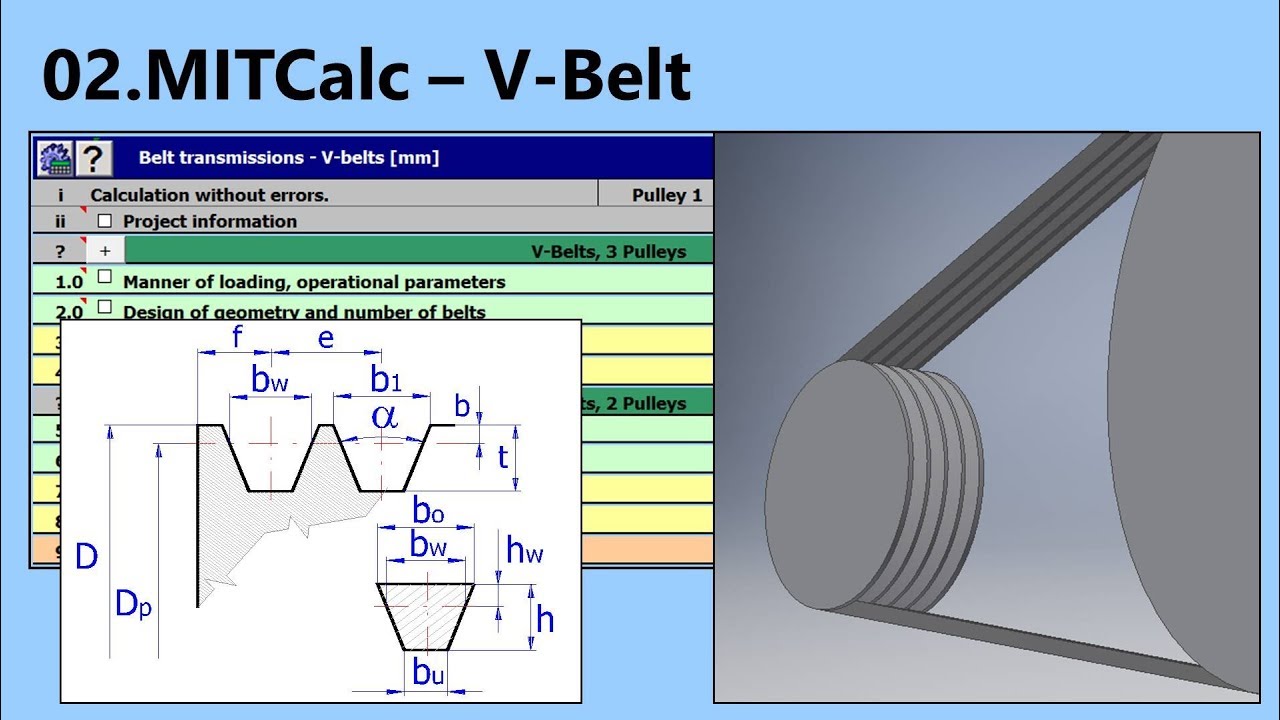

V Belt Calculation And Design Mitcalc 02 Youtube

Pd design power as determined in Section 311 W belt weight per foot of length lb.

. For example if Pulley 1 is 6 diameter and spins at 1000 RPM and you need to find Pulley 2 size to spin it at 500 RPM enter Pulley 1 6 Pulley 1 RPM 1000 Pulley 2 RPM 500 and hit Calculate to find Pulley 2 diameter. Small sheave pitch diameter inches n. By an Hutchinson skilled engineer experienced in drive belt systems.

Belt Speed V d x n 382 V. V Belt Pulley Belt Pulleys Belt Pulley V Belt Pulley V Belt. FIRST APPROACH FOR ELECTRIC ENGINE.

The corrected horsepower rating of one belt is obtained by multiplying the horsepower rating from Tables 9 through 12 by the arc of contact correction factor and by the length correction factor. 14 Set the mode of loading and operational parameters type of drive length of operation efficiency etc. Ad We Researched It For You.

RPM of small sheave Power HP Pe x V 33000 HP. The above image illustrates which dimensions we need and each is colour coded to half make. We will need to know the diameters of the pulleys as well as the belt length.

Calculate distance between pulleys. Other belts Flexonic Conveyxonic. All the page number talked about are from Design Data Book.

Belt speed v π D 1 n 1. Torque pounds-inches n. Click slider to select then use Keyboard Cursor Keys to Fine Tune Centers Decimal Fraction.

Shaft load F a. Maximum power capacity in KW of a V-belt using the formula given in Table in pg no. Smallest belt wrap angle α.

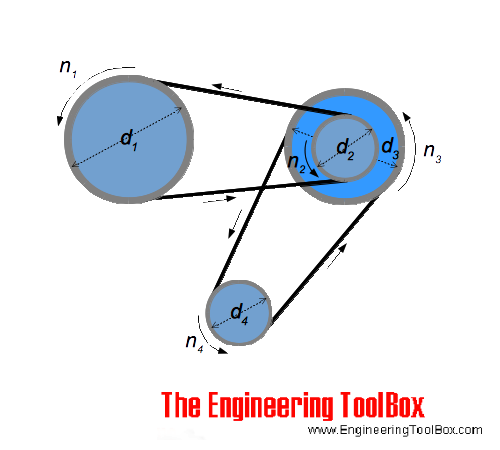

V-belts trump flat belts with their small center distances and high reduction ratios. If you know any 3 values Pulley sizes or RPM and need to calculate the 4th enter the 3 known values and hit Calculate to find the missing value. If we need to calculate the distance between the centres of the two pulleys then we can use the following calculations to approximate this.

Belt slip is defined by built-in slip table. 762 where S Belt speed 2676 ms de dp x Fb dp diameter of the smaller pulley Fb Small diameter factor for speed ratio of 4235 From Table 114 355 x 114 de 4047 Power Kw 322 x 2676009 - 478 x 10-4 x 26762 Power 2144 kW f6. Belt speed feet per minute Torque Tq Pe x d 2.

Find Out What You Need To Know - See for Yourself Now. Typical calculation design of a transmission using a V-belt consists of the following steps. Smartphone version on Apple Store and Google Play Store.

The preferred center distance is larger than the largest pulley diameter but less than three times the sum of both pulleys. Convert the value from torque Tq or horse power PS into kW with the formula below. Horsepower HP Tq.

Enter power parameters of the transmission transferred power speed. The belt speed change due to slip is neglected. Horsepower HP Pe.

We researched it for you. The value of transmission power used in designing is the power requirement of the driven machine if obtained or the power of driving unit engine or motor. Optimal speed range is 10007000 ftmin 3002130 mmin.

Belt speed feet per minute d. This approach is only valid for electric engines and Poly V belts. For example if Pulley 1 is 80mm diameter and spins at 1000 RPM and you need to find the Pulley 2 size to spin it at 400 RPM enter Pulley 1 80 Pulley 1 RPM 1000 Pulley 2 RPM 400.

Ad Free Shipping On Power Tools. The belt slip occurs on the driver pulley so the speed of all driven pulleys and idlers is influenced by the same slip. Repair Services Also Available.

Names A Wide Selection. The number of belts required for an application is obtained by dividing the design horsepower by the corrected horsepower rating for one belt. 14 Initiate Automatic design of the transmission.

Effective pull pounds V. V W N V P 1 60 09 10 3 2 where. 33 Pulley Groove Pitch Width I.

The line in the V-belts or wedge belts whose length remains unchanged when the belt is defor- med under tension 32 Pitch Width of Belt I The width of the belt at its neutral axis. V belt speed fpm 12 Driver RPM Driver Pitch Diameter in π. Ad Shop Motor Control Solutions For Your V-Belts and V-Belt Pulley Needs.

Design process for Classical V-Belts Narrow V-Belts. Drive torque P2πn 1 Nm. V belt Design HP Variables Declarations Nsf Service life factor a Belt constant obtain from mfg c Belt constant obtain from mfg e Belt constant obtain from mfg D1 Small sheave pitch diemeter Kd Small diameter factor estimate or manufacture tables for given velocity ratios Vmfpm Belt speed Notes.

Belt Length and Center Distance Calculator Belt Pulley D Pitch Diameter Large Pulley d Pitch Diameter Small Pulley C Center Distance L Belt Pitch Length Center Distance Known Belt. See Table 2 below for typical values. Drive force T 1-T 2 Pv.

Driven pulley speed Driven pulley output power P i P xi F p v η t 1 - s Built-in slip table It is assumed that. Our Application Technology experts offer you free support service regarding the application of our products and also help. V-belts need larger pulleys for their thicker cross-section than flat belts.

Ad Shop Zoro For Exclusive Offers on Millions of Everyday Products. V-BELT DRIVES This technical manual contains all important technical information and methods for the design and calculation of drives with Optibelt V-belts and V-grooved pulleys for industrial applications. RPM of small sheave Power HP Tq x n 63025 HP.

V Belts Design Procedure Youtube

Belt Pulley Calculation Saygili Rulman

Belts Pulley Diameters Vs Speed

V Belts Design Requirements For Power Requirements Angle Between Sheave

V Belts Design Requirements For Power Requirements Angle Between Sheave

0 komentar

Posting Komentar